If you’ve been debating how to improve warehouse storage at your facility, you’ve probably come across pallet racking. It’s one of the most fundamental and universal ways to manage inventory storage in the warehouse. Since pallet racking systems are so versatile, they are among the best storage options for most general industry warehouses. They also offer surprising benefits. Wondering how to improve warehouse productivity, too? Selective pallet racking provides the logical organization and ease of access needed to improve picking speeds, thereby boosting your efficiency alongside your capacity.

Jump to Section:

- What Is a Pallet Racking System?

- Advantages of a Pallet Racking System

- Applications for Pallet Racking Systems

- Equipment Solutions From Cherry’s Material Handling

- Buy a Pallet Racking System Today From Cherry’s Material Handling

What Is a Pallet Racking System?

First off — what is pallet racking? At its core, a pallet racking system is a multilevel storage system used in material handling. It allows warehouses to take advantage of vertical space to maximize storage capacity. A pallet rack consists of two primary components — horizontal beams and vertical frames, sometimes called “uprights.”

Each pair of beams can hold a row of palletized product. These heavy-duty rails sit in parallel rows to create shelves. They’re adjustable to accommodate various heights from the ground and between racks. Pallet racking beams come in two styles. The box beam has a perfect rectangular shape, while the step beam has an inset “step” along the inside of the beam. A step beam allows a racking system to include wire decks. These wire panels sit flat along the step beams, increasing the surface area beneath the pallets and acting as a safety net if anything falls off the pallet.

Pallet rack uprights, or columns, are the side supports for the racking system. They come in various heights, depths and post sizes to accommodate different warehouse ceiling heights, pallet sizes and load capacities. The structure makes it simple for warehouse forklift drivers to deposit and remove pallets of inventory as needed.

While pallet racks come in many different varieties, the most popular is teardrop pallet racking. As the name suggests, teardrop uprights have slide-in, teardrop-shaped holes along the vertical poles. The shape allows warehouses to slide and lock horizontal beams into place for fast assembly. The “pallet racking system” refers to the organizational method used to store the palletized product in the warehouse.

The most commonly used pallet racking system is selective racking. In this configuration, the pallet racks are in aisles, allowing forklift drivers to drive through and grab any pallet needed. This organizational method works best for the most widely used inventory management method, the first-in, first-out (FIFO) system. In this setup, the oldest pallets of product are still easily accessible, allowing warehouses to move products efficiently without blocking access to the oldest inventory. Selective racking also allows two racks to sit abreast, making for double-wide storage shelving.

Advantages of a Pallet Racking System

Wondering how to increase warehouse safety and improve warehouse profitability, storage and productivity all at once? The distinct benefits of pallet racking provide the solutions you’re looking for.

1. Improved Productivity

How do pallet racking systems improve efficiency? Pallet racks are one of the most convenient warehouse storage solutions. They enable forklift drivers to travel throughout the warehouse without obstruction and find the pallet needed from among the shelves. They’re an excellent solution for warehouses with a broad product selection in their inventory because the selective storage method makes everything easily accessible.

Because pallet racks hold just one row of pallets, every pallet remains accessible. They’re also removable from either side. When the racking system has an aisle configuration, it helps reduce congestion in a busy warehouse. If a forklift driver encounters another machine in one corridor, they can drive to the next one down to access the pallet they’re retrieving.

Pallet racking systems significantly reduce stock-picking time, which contributes to efficient order fulfillment. Through consistent organization, it’s easier to keep track of pallets. As a result, less inventory goes missing, and forklift drivers and pallet truck operators can find the merchandise they need faster.

2. Maximized Space

Perhaps the most sought-after advantage of pallet racks is storage space optimization. Warehouses have high ceilings, and pallet racks, alongside other material handling equipment, let them use this space for storage. At Cherry’s Material Handling, we can supply uprights ranging from 8 feet to 20 feet, and even higher depending on your facility’s airspace. Add and subtract beams to accommodate pallets stacked to different heights.

A considerable benefit of pallet racks is that they’re a solution to the age-old question of how to improve warehouse profitability. By increasing your storage capacity through vertical shelving, you also boost your inventory density. You won’t need to invest in a larger warehouse to store products, meaning you’ll save on storage costs, real estate and all the overhead costs that go into maintaining a larger facility.

3. Optimal Safety

A messy, disorganized warehouse is a safety hazard. It makes it challenging for warehouse workers and machinery to maneuver and increases the chances for trips, slips and falls. Organizing your inventory into pallets makes your facility safer. Inventory storage, especially vertical storage, requires serious precautions. Pallet racking systems are durable and can carry heavy loads stored at heights, which increases safety. We recommend selecting racks graded for a heavier weight load than you require.

You can outfit your pallet racks with wire decks, increasing the surface area under the pallets to support additional weight. Depending on the situation they may also catch an item that comes loose from the pallet before it tumbles to the floor. For added stability and safety, fix pallet racks to the floor.

4. Inventory Protection

Organizing your stock reduces the chances it will get damaged. Storing it above floor level provides added protection. Your inventory won’t encounter spills on the floor, and forklifts won’t bump into it while driving. The racks themselves are also quite sturdy, resisting damage from impacts.

The selective pallet racking system causes less inventory to expire. Since every pallet is accessible from both sides of the aisle, your workers can grab the oldest products as quickly as the newest. New deliveries never block access to the existing stock, which makes the FIFO inventory management system possible. You’ll reduce shrinkage by moving items quickly and maintaining a high turnover rate.

5. Easily Expanded Capacity

Pallet racking’s design makes it easy to increase your capacity at any time. While pallet racks come in many heights and configurations, they’re modular and available in standard shapes and sizes. Easily add rows, make longer aisles or push two frames together to hold more inventory. Add and remove beams to create more tiers at different heights to change which products you store in particular aisles. Universal pallet racking system components, such as flared wire decking, let you upgrade the pallet racks in your warehouse, even when they’re different designs.

6. Flexible Storage

Many warehouses cycle through different types of inventory throughout the year. Sometimes they stop carrying specific products and replace them with others. Maybe a supplier changes packaging or how many items get sold as a unit. Any of these changes call for different-sized shelving to accommodate the various products and their dimensions. The beams need to be able to support the weight safely. Pallet racks are easy to adjust, letting you store varying heights and weights within the same standard frames.

Cherry’s Material Handling offers customized solutions to help you gain even more flexibility from your pallet racking system, even if you have highly specific storage requirements.

Applications for Pallet Racking Systems

The selective pallet racking system is one of the most versatile storage methods available for industrial settings. As a result, warehouses, manufacturers and retailers across all sectors use pallet racking.

- Warehousing: A common concern for warehouses is increasing storage density. With the rise of e-commerce, warehouses are expanding. Subsequently, real estate prices for industrial warehousing are also rising. Selective pallet racking provides a solution, allowing warehouses to increase storage capacity using vertical space.

- Manufacturing: Many manufacturers need adequate storage for their raw materials and finished goods. A selective pallet racking system can be useful, since manufacturers need to track various materials, differently sized products and custom orders.

- Retail: Pallet racks make sense for back-room storage in big-box stores and can also be useful in warehouse-style retail settings. Since they can handle products of any volume, weight or size, they’re an excellent solution for the wide product selection a retailer might offer.

Equipment Solutions From Cherry’s Material Handling

At Cherry’s Material Handling, we offer all the components needed to construct a safe and effective pallet racking solution for your warehouse. Our selection of frames can reach a range of heights and depths. We also offer accessories to provide additional support for pallets and protection for the racks themselves.

Selective pallet racks are incredibly versatile and come in a range of standard specifications to meet most industries’ needs. However, at Cherry’s, we also recognize your storage solution should solve 100% of the problem. If you need a specialized solution, we offer tailored pallet racking systems and work to meet your industry’s and company’s needs. Whether it’s custom-engineered wire decking or another part of your pallet racking system, count on us to deliver. Feel free to call us at 877-350-2729 or contact us online to discuss your unique pallet racking needs and specifications.

Our solutions include the following.

Step Beams

Our step beams for pallet racks come from reliable, American-based manufacturers, and we’ve personally tested many of them in real-world conditions with our team of in-house engineers. With load capacities between 4,056 and 9,370 pounds, they have excellent durability and strength. They range in length from 96 to 144 inches. They consist of roll-formed steel and feature a continuous seam weld on the base. Their powder-coated, baked-on finish adds to their durability by preventing corrosion.

Our step beams offer many benefits to help you increase warehouse safety. Their integrated safety locking pins, located on both ends, keep the beams securely in place and your workers and your inventory safe. Their construction provides stability, and their bright orange finish offers maximum visibility.

Teardrop Frames and Uprights

Our teardrop uprights and frames feature 13-gauge cold-rolled steel construction. The material offers a smoother surface, more tensile strength, tighter dimensional tolerances and a straighter design. For added strength and security, the frames have welded joints. For storage flexibility, the uprights have 2-inch increments to give you the most customization of shelf height. To improve stability, they have diagonal braces that prevent swaying even under heavy loads. They also feature a bolt-on footplate to keep them permanently in place.

Pallet Support Bars

One safety hazard many warehouses face with pallet racking is supporting heavy loads. When a pallet carries a lot of weight and rests on two horizontal beams, it can buckle and break in the center, damaging products and potentially injuring workers. So, how can you increase warehouse safety with your pallet racks?

Cherry’s Material Handling offers pallet support bars as a solution. They can support heavily loaded pallets, those nearing the end of their operational life and nonstandard- or international-sized pallets. These 14-gauge steel bars bridge the selective racking system’s depth, connecting the two support beams to add extra surface area and support under the pallets. These crossbeams install in pairs to provide even support for each pallet. Besides pallets, they can also hold up plywood shelving, so you can use your pallet racking system to store some loose items.

Our pallet support bars are 2 inches wide and come in lengths ranging from 36 to 48 inches. They can support between 1,250 and 1,550 pounds. Their double flange design is compatible with step beams and features a tek screw to lock them into place.

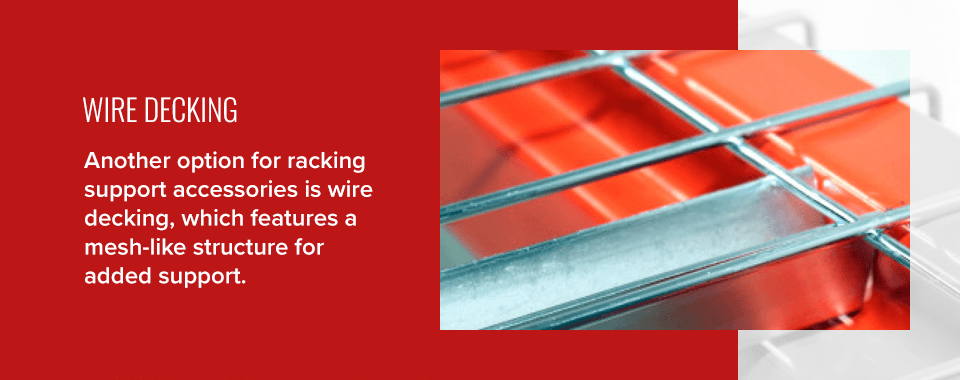

Wire Decking

Another option for racking support accessories is wire decking, which features a mesh-like structure for added support. Many warehouses prefer wire decking over pallet support bars when they worry about loose items falling off their pallets. The mesh wire decking catches things that come loose from the loaded pallet, preventing product damage and safety incidents alike. Another safety feature of wire decking is the mesh design allows for proper air circulation to prevent humidity buildup. It will also enable sprinklers to reach the entire facility in the case of fire.

We offer three types of wire decks.

- Step channel: This style of wire decking fits within the instep on your step beams. They come in thicknesses ranging from 1.5 to 1 5/8 inches. Step channel wire decking can safely support 2,500 pounds per deck, equivalent to a pair of 48-inch pallet support bars.

- Flared and universal: With a design able to fit step beams, box beams and many other shelving designs, our flared and universal wire decking is versatile and practical. It comes in various sizes, including 24-inch, 30-inch, 36-inch, 42-inch, 44-inch and 48-inch deep models, and can support 2,500 pounds.

- Inverted channel: For inventory that needs protection from dirt and moisture, inverted channel wire decking provides the best solution. Its inverted U-channel supports prevent dust, debris and crumbs from collecting within the decking. Inverted channel wire decks allow for up to 3,500 pounds of storage per unit should the storage needs demand it.

Rack Protectors

In a busy warehouse with lots of foot traffic and material handling equipment like forklifts, lift trucks and pallet trucks driving around, your racks need protection. Our selection of industrial rack protectors preserve your racks’ structural integrity by shielding the uprights from impacts, nicks and bumps. Most rack protectors wrap around the base of the vertical frame.

Metallic rack protectors feature pre-drilled holes, allowing them to anchor into place. We have heavy-duty protectors suitable for high-traffic areas such as the ends of aisles. The structural cast aisle protectors offer reinforcement and deflect bumps at the same time. We also provide a polyethylene plastic rack protector. It’s lightweight and easy to install, with no anchor bolts. Instead, it straps into place. Thanks to rack protectors’ design, you can position them on the ground or around the horizontal beams to protect against bumps from forklift arms.

Buy a Pallet Racking System Today From Cherry’s Material Handling

Cherry’s Material Handling has the pallet racking products you need to get the job done, all available from our e-commerce store. We offer reliable, durable, American-made industrial products and material handling equipment for your warehouse. Browse our collection of pallet racking solutions and buy online today.