No matter what industry you work in, eventually, you’ll need some sort of reusable containers to store your products or supplies. In most cases, you’re going to choose one of two options — collapsible or noncollapsible. What is the difference, and how can you choose the right one for your application?

This work is licensed under a Creative Commons Attribution-NoDerivs 3.0 United States License.

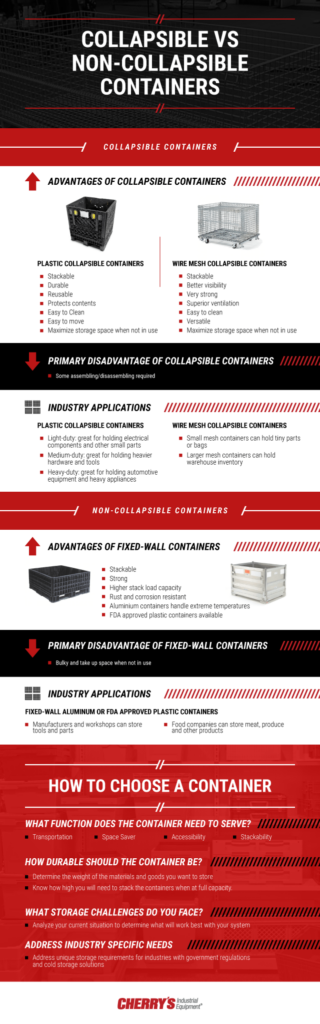

Collapsible Containers

There are plenty of benefits of collapsible containers. They’re durable, lightweight and reusable. They protect their contents while being easy to clean and — while empty — easy to move. When they’re not in use, you can collapse them, maximizing your storage space.

Wire-mesh collapsible containers are strong and offer better visibility and ventilation. They’re easy to clean and incredibly versatile, depending on your needs. Like collapsible plastic containers, the collapsible wire container is stackable up to so many levels, depending on its specific design and construction. To get the specifics regarding the number of levels each collapsible container can stack at full capacity, please visit the container section of our site.

Collapsible container applications will vary depending on your needs. Light-duty plastic containers are ideal for electrical components and other small parts, while medium-duty containers can hold heavier hardware and tools. Heavy-duty plastic containers are useful for automotive parts and appliances. Small wire-mesh containers, on the other hand, are perfect for tiny bags and parts. Large wire-mesh containers work well for warehouse inventory.

Noncollapsible Containers

Fixed-wall noncollapsible containers are rigid and strong, and in many cases have a higher load capacity than standard collapsible plastic or mesh containers. Aluminum noncollapsible containers, for example, are naturally resistant to rust and corrosion and can handle temperature extremes without warping or losing structural integrity.

Due to its robust design, these noncollapsible containers are heavy and bulky and tend to take up space when not in use.

Manufacturers and workshops often choose fixed wall containers for storing tools and parts. In the case of food service industries, FDA-approved plastic or nonreactive aluminum containers are ideal for storing meat, produce and other products.

How to Choose a Container

Now that you know the different options, how can you choose a container for your application? Which will work best when you compare collapsible vs. noncollapsible containers? First, you’ll need to ask yourself a few questions.

What function will this container need to serve? Are you using them to transport items, to save space or so the products they contain are more accessible? Do they need to be stackable?

Next, ask yourself how durable the containers need to be. What is the maximum weight that will be put into the containers? Another thing to consider is how high will your containers need to be stacked if loaded to full capacity. For example, some containers can be stacked up to 3 levels high while others can be stacked 4 levels or higher. Be very diligent to research this information prior to making your final decision.

What storage challenges will you be facing? Take the time to analyze your current storage situation to see what will work best with your system. Your needs won’t be like anyone else’s, so this is something that will need to be assessed on a case-by-case basis.

Finally, address any industry-specific needs when it comes to storage. Some sectors are subject to more intense scrutiny and must abide by government regulations when choosing storage solutions.

Choose Wisely

Collapsible and noncollapsible storage containers both have their place in a variety of industries. Take a closer look at your needs to figure out which ones will work best for you.

Need help choosing the right container for your unique application? Contact Cherry’s Industrial Equipment today to learn more.